Stage 6

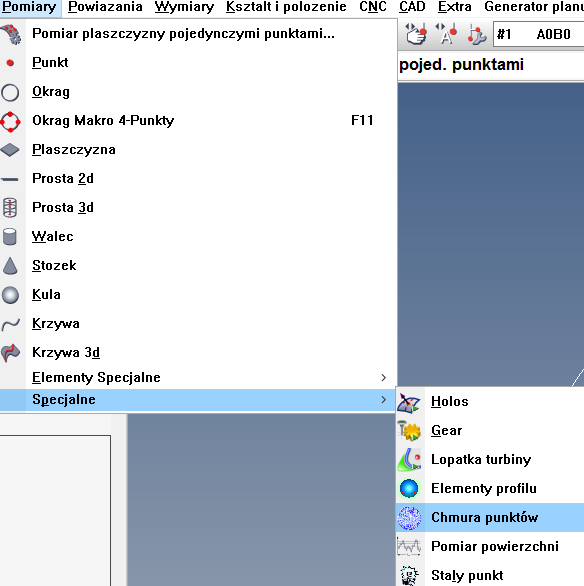

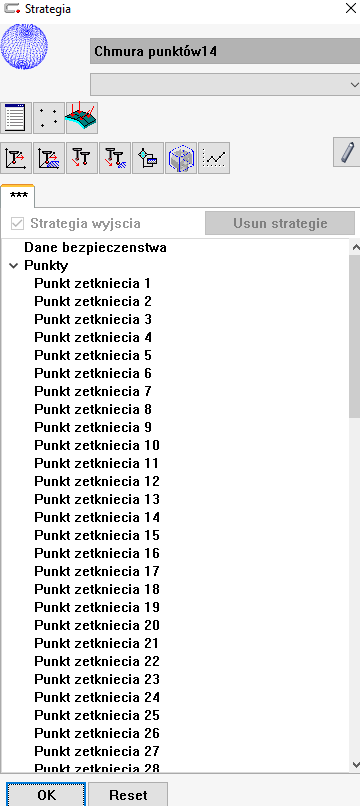

- The “Point Cloud” measurement element of the Calypso software was used to conduct non-contact measurements (Fig. 1).

Fig. 1

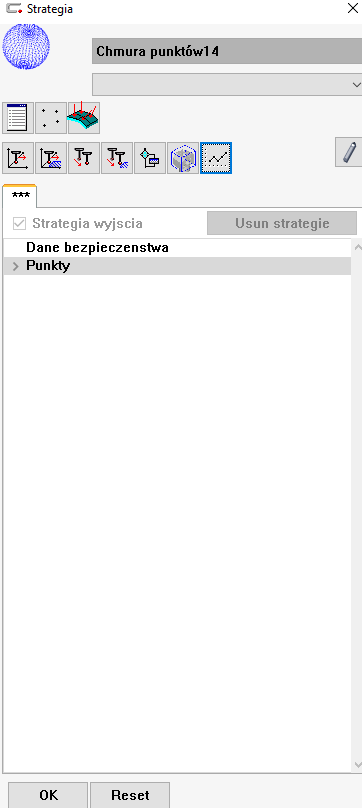

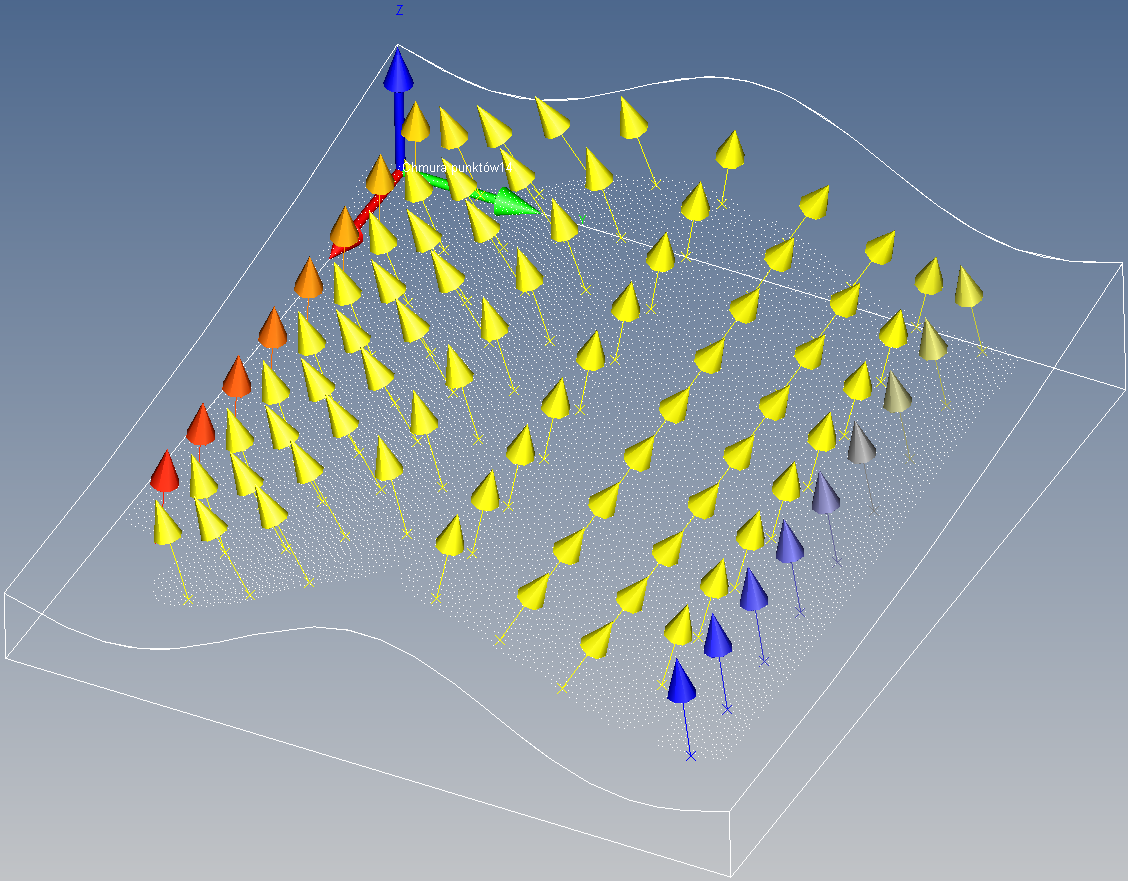

- The point cloud was measured by using the measurement strategy based on faces (Fig. 2). The user of the CMM had to select upper surface of the nominal model of the measured part to generate measurement points distributed along the investigated surface. Moreover, the distance between points and the borders of the curvilinear surface had to be defined.

Fig. 2

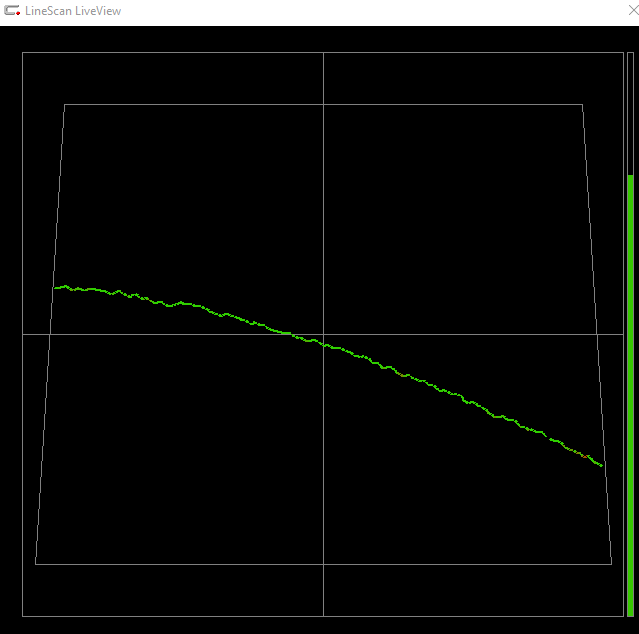

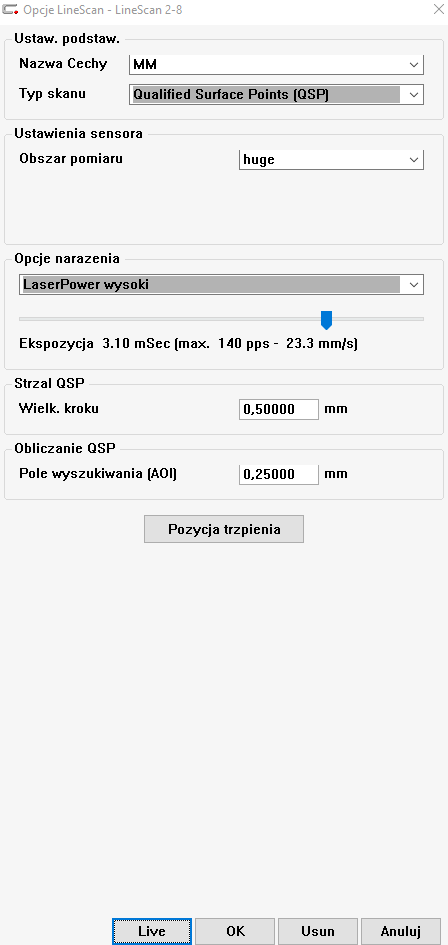

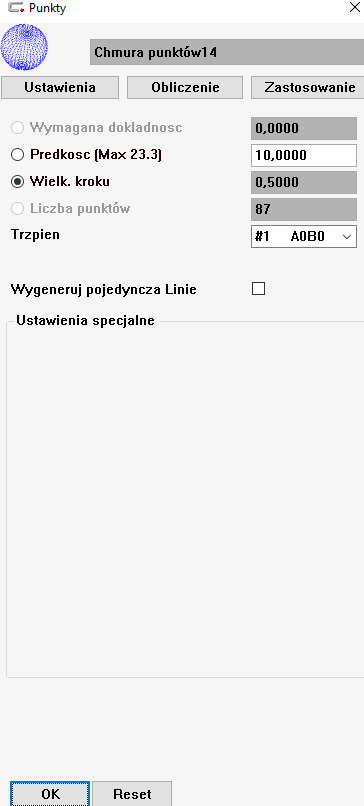

- The measurement parameters applied for non-contact measurements were selected based on the “Live View” option available in the Calypso software (Fig. 3). The green colour of the profile of the measured surface of the part means that the exposure time is correct. The user of the applied measuring system defined, among others, the measuring field (Fig. 4).

Fig. 3

Fig. 4

- The defined measurement strategy prepared for non-contact coordinate measurements of the upper surface of the measured part is presented in the figures 5 and 6.

Fig. 5

Fig. 6

- When determining the measurement strategy the user of the CMM had to select the scanning speed (Fig. 7). The scanning velocity is one of the parameters having the influence on the final results of the non-contact measurements conducted by using the LineScan measuring probe.

Fig. 7

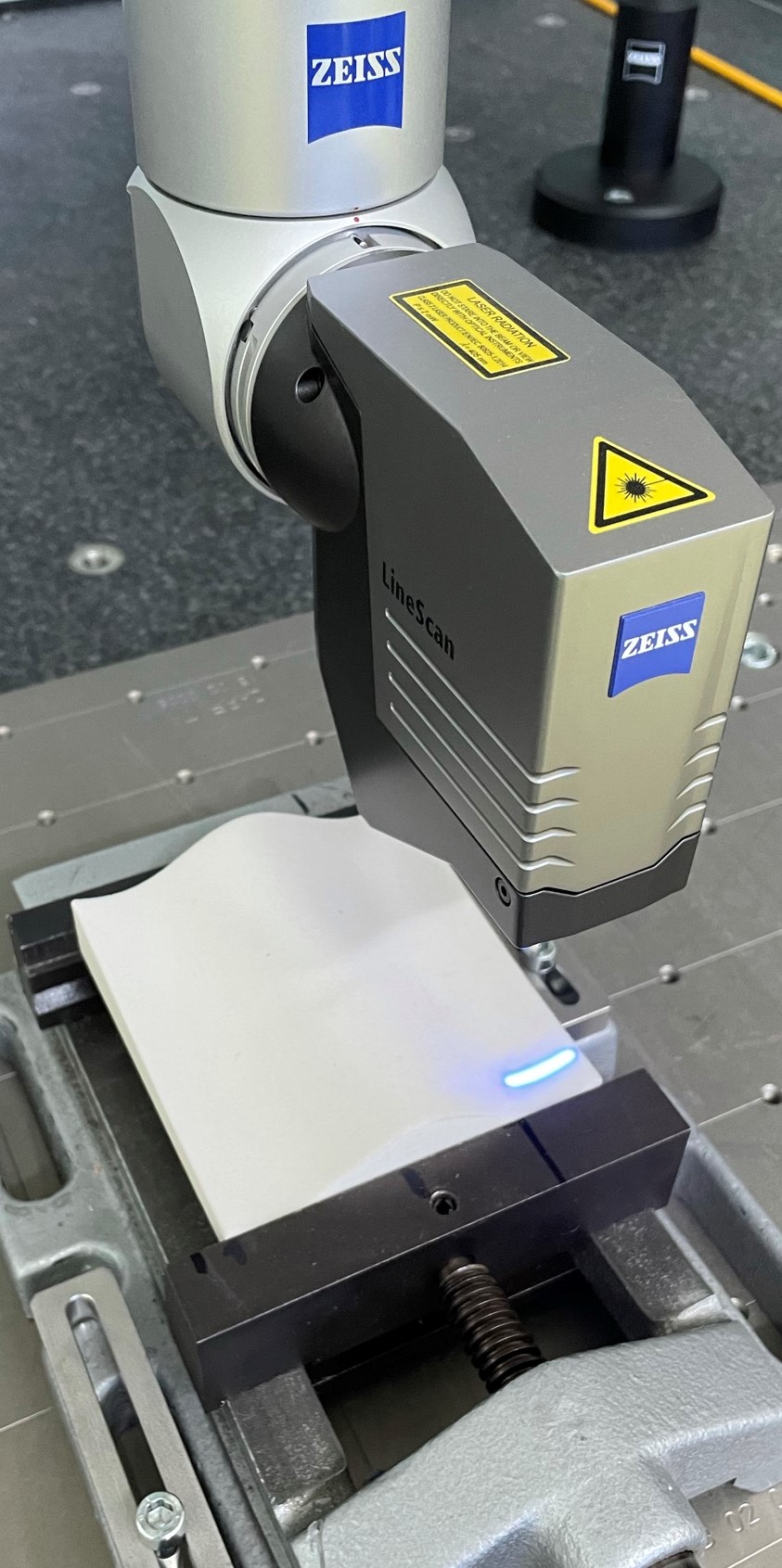

- The figure 8 presents the real coordinate measurements of the upper surface of the part.

Fig. 8

Last modified: Thursday, 4 August 2022, 2:27 PM