Stage 1

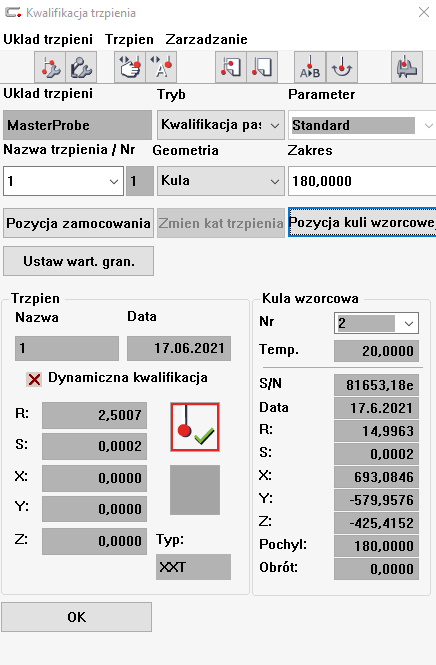

- The first stage of the measurements concerned the qualification process of the stylus system used to determine the coordinate system of the measured product. The coordinate system of the part was measured in the contact mode by means of the VAST XXT measuring probe. The qualification starts with defining the position of the reference sphere by using the reference stylus. The next figure presents the functions of the Calypso software applied for performing the qualification process. The name of the reference stylus was “MasterProbe”. The quality of the first step of the qualification process was determined by analysing the value of the S parameter (a standard deviation).

Fig. 1

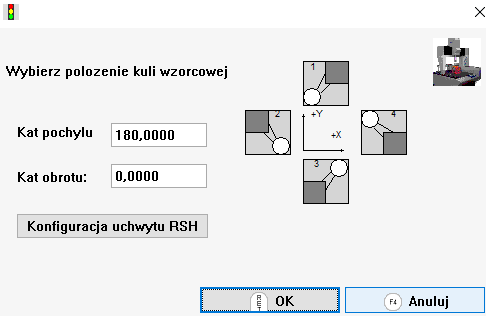

- The user of the measuring system had to select the position of the reference sphere on the table of the CMM before starting the first stage of the qualification (Fig. 2). In the case of the performed measurements, the first position was selected. The user had to remember to use the reference sphere dedicated to contact measurements. While using different probes cooperating with the CMM different reference spheres may be applied. The number of the reference sphere must be specified before the qualification.

Fig. 2

- The first stage of the real qualification process is presented in the figure 3. The user of the CMM had to select one point on the reference sphere located on its top. Other points were measured automatically in the scanning and single-point probing modes.

Fig. 3

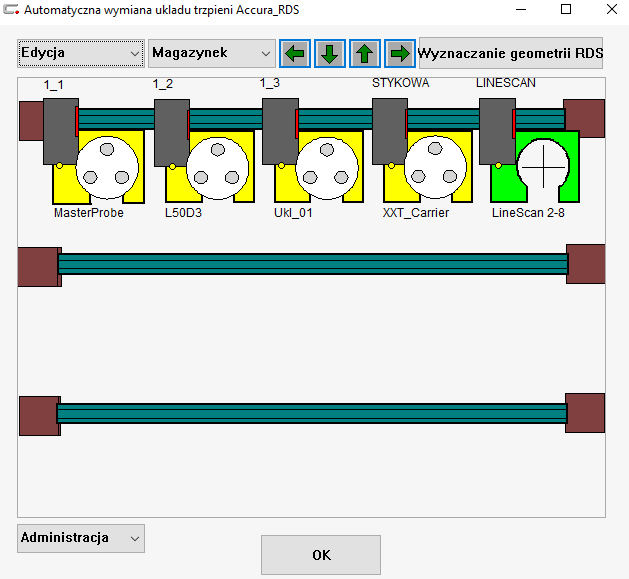

- After conducting the first stage of the qualification the user of the CMM had to change the stylus in order to determine the coordinate system of the measured part. The next stylus system also had to be qualified. The changing process was conducted automatically by using the functions of the Calypso software (Fig. 4). The user selected the stylus system named “Ukl_01”. The stylus system was composed of only one stylus and mounted in the VAST XXT measuring probe. The axis of the stylus was parallel to the Z axis of the CMM.

Fig. 4

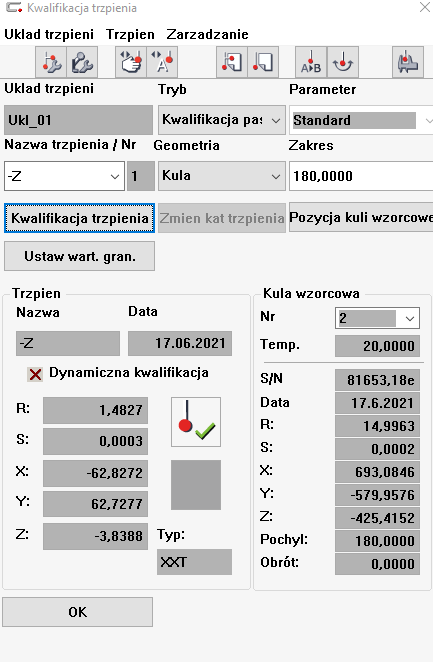

- The second stage of the qualification process was conducted by using the same reference sphere which was applied for the first step. The results of the qualification process, apart from the standard deviation (S), are as follows: R (a radius of the stylus), X, Y, Z (coordinates of the centre of the qualified stylus in relation to the reference position determined during the first stage of the qualification) (Fig. 5). The radius is used to perform the probe radius correction process, the aim of which is to calculate the coordinates of the corrected measurement points based on indicated measurement points representing the centre of the stylus during its contact with a measured surface.

Fig. 5

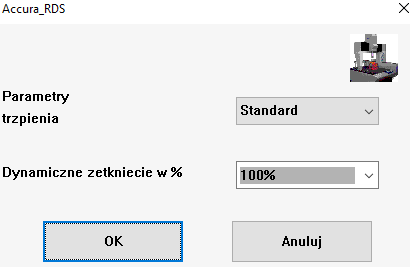

- The qualification was performed in the standard mode as it is indicated in the figure 6.

Fig. 6

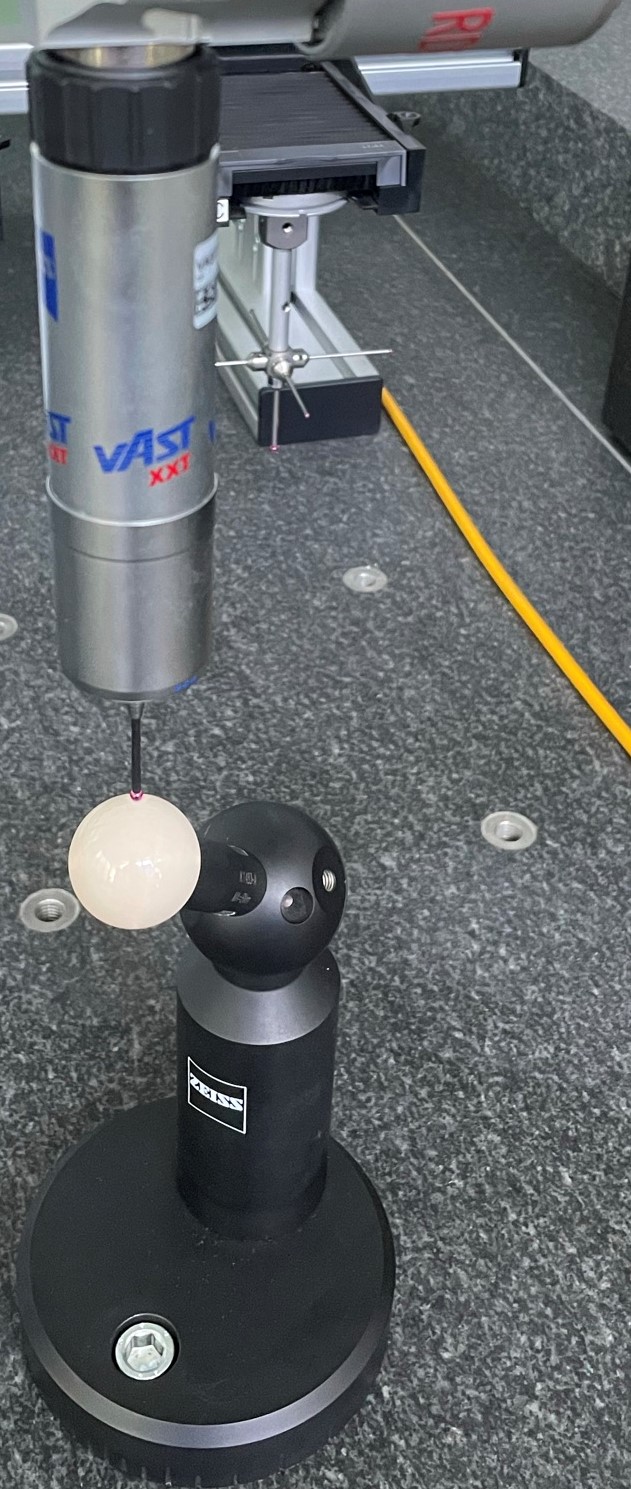

- The figure 7 presents the second stage of the real qualification process. As in the case of the first step, the user of the CMM had to select only one point on the reference sphere manually. The second stage was conducted in the scanning and single-point probing modes. Points, distributed on the reference sphere, were measured in the CNC (ang. computer numerical control) mode.

Fig. 7

Last modified: Thursday, 4 August 2022, 2:25 PM