Short introduction presenting a considered example

The aim of the example is the presentation of the stages of the coordinate measurements of the upper curvilinear surface of the part produced by using the rapid prototyping. The measurements were conducted by means of the coordinate measuring machine (CMM) ACCURA II of the Carl Zeiss company.

Students obtain the knowledge regarding programming of the CMM, non-contact measurements, analysis of results of measurements and factors having the influence on the final results of non-contact coordinate measurements.

Moreover, the example shows preparatory activities which have to be conducted before non-contact measurements. They were conducted by using the contact measuring probe of the applied CMM.

Additionally, the example presents the fundamental functions of the Calypso inspection software, cooperating with the ACCURA II CMM, enabling both contact and non-contact measurements.

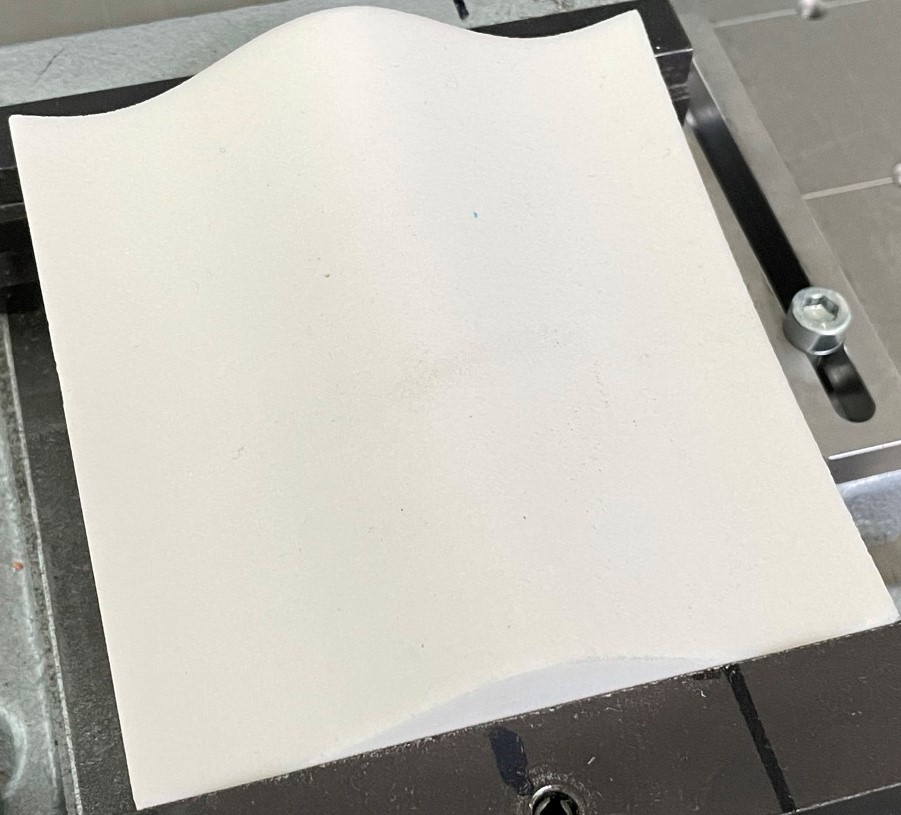

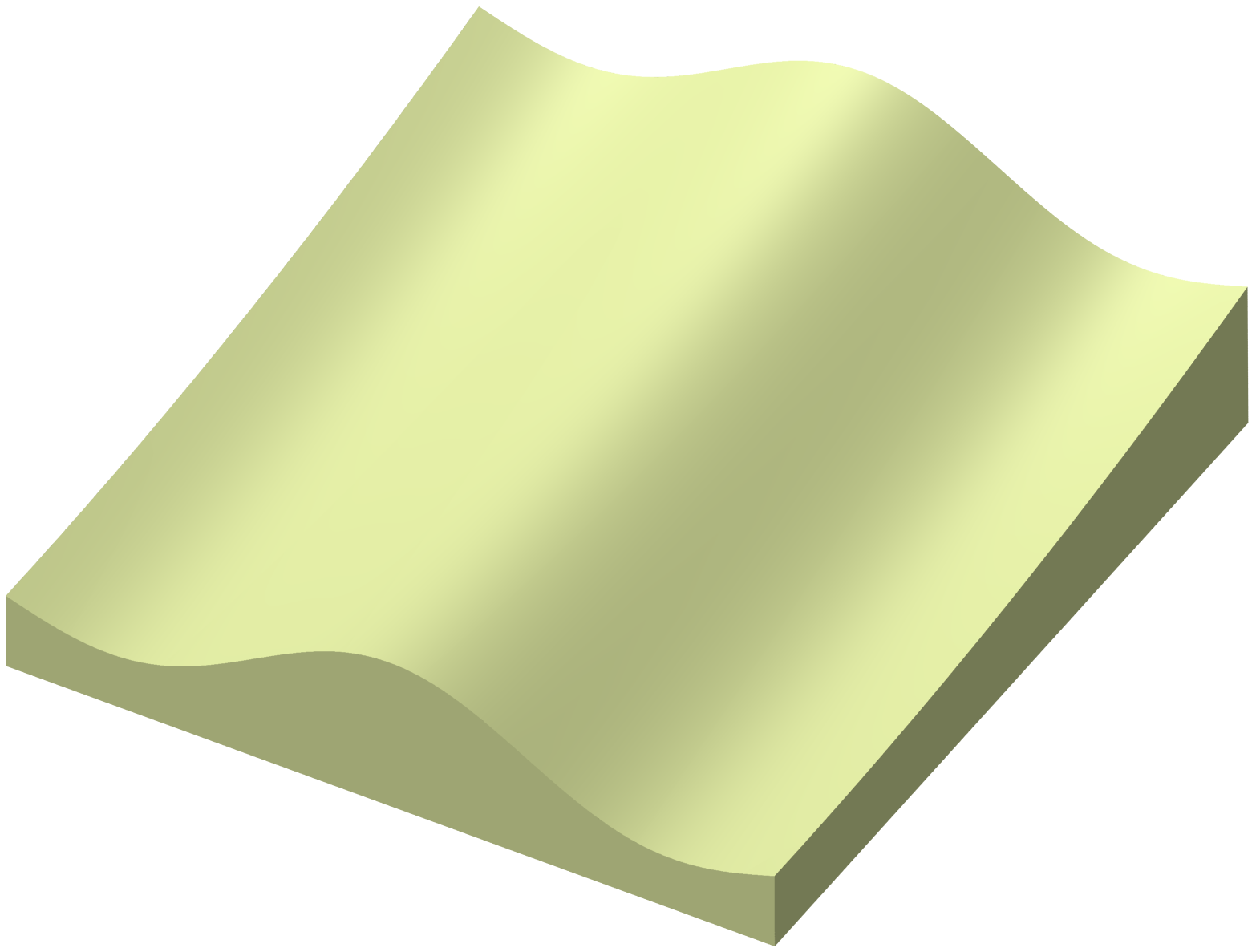

The measured object is presented in the following figures.